Powermax45 XP plasma cutter

The Powermax45® XP 45-amp plasma power supply was last manufactured in March 2024, and is no longer available for sale from Hypertherm. We continue to make original replacement torches, consumables, and repair parts. Refer to the Torches and consumables section for additional upgrade options.

Hypertherm's Technical Service department still continues to support this model.

System information

Product lifecycle

Affected power supply part numbers:

088093, 088106, 088094, 088107, 088109, 088092, 088104, 088095, 088110, 088105, 088158, 088160

Affected system part numbers:

088093, 088106, 088107, 088092, 088104, 088105, 088094, 088108, 088109, 088095, 088173, 088110, 088111, 088158, 088160, 088130, 088132, 088131, 088133, 088144, 088146, 088145, 088147, 088141, 088134, 088135, 088136, 088139, 088140, 088155, 088148, 088149, 088156, 088150, 088153, 088154, 088112, 088114, 088124, 088113, 088115, 088126, 088128, 088127, 088129, 088121, 088116, 088117, 088122, 088118, 088123, 088119, 088120, 088159, 088161

| AVAILABILITY | |

|---|---|

| Power supply | ⊗ |

| Original torch | ✔ |

| Service parts | ✔ |

| Consumables | ✔ |

| Technical support | ✔ |

Specifications

| Input voltages (± 10%) |

CSA |

200–240 V, 1-PH, 50–60 Hz 480 V, 3-PH, 50–60 Hz1 |

|---|---|---|

| CE/CCC |

230 V, 1-PH, 50–60 Hz 400 V, 3-PH, 50–60 Hz |

|

| Input current @ 6.5 kW |

CSA |

200–240 V, 1-PH, 39/32 A 480 V, 3-PH, 9.4 A1 |

| CE/CCC |

230 V, 1-PH, 33 A 400 V, 3-PH, 10 A |

|

| Output current | 10–45 A | |

| Rated output voltage | 145 VDC | |

| Duty cycle @ 40° C (104° F) |

CSA |

50% @ 45 A, 200–240 V, 1-PH |

| CE/CCC | 50% @ 45 A, 230 V, 1-PH 60% @ 41 A, 230 V, 1-PH 100% @ 32 A, 230 V, 1-PH 50% @ 45 A, 400 V, 3-PH 60% @ 41 A, 400 V, 3-PH 100% @ 32 A, 400 V, 3-PH |

|

| Open circuit voltage (OCV) |

275 VDC (200–240 V, CSA/CE/CCC and 480 V, CSA) 265 VDC (400 V CE/CCC) |

|

| Dimensions with handles | 442 mm (17.4″) D x 173 mm (6.8″) W x 357 mm (14.1″) H | |

| Weight with 6.1 m (20′) torch | CSA | 14 kg (31 lbs.) |

| CE/CCC | 15 kg (33 lbs.) | |

| Gas supply | Cutting: air (clean, dry and oil-free), nitrogen, F5 Gouging: air (clean, dry and oil-free), nitrogen, F5 Marking: air (clean dry and oil-free) argon |

|

| Recommended gas inlet flow rate/pressure |

188 I/min (400 scfh) @ 5,9 bar (90 psi) | |

| Input power cable length | 3 m (10′) | |

| Power supply type | Inverter – IGBT | |

| Engine drive requirement | 12.5 kVA (10 kW) for full 45 A output | |

| Electrical efficiency | 88% | |

| Recyclability | 100% | |

| Certifications |

CSA certified for use in the Americas and Asia, except China. CCC for use in China. CE, RCM, GOST-TR, UkrSEPRO, and Serbian AAA for use in Europe, Australia, Belarus, Kazakhstan, Russia, Serbia, Ukraine, and other countries where accepted. |

|

| Warranty | Power supply: 3-year Torch: 1-year |

|

1 For use in North America only.

Engine-driven generator operation

| Engine drive rating | System output current | Performance (arc stretch) |

|---|---|---|

| 10 kW | 45 A | Full |

| 8 kW | 45 A | Limited |

| 6 kW | 30 A | Full |

Cut capacity

| Capacity | Thickness | Cut speed |

|---|---|---|

| Cutting | ||

| Recommended | 16 mm (5/8″) 22 mm (7/8″) |

500 mm/min (20 ipm) 250 mm/min (10 ipm) |

| Severance (hand cutting) | 29 mm (1-1/8″) | 125 mm/min (5 ipm) |

| Pierce* | 12 mm (1/2″) | |

* Pierce rating for handheld use or with automatic torch height control.

| Capacity | Metal removal rate | Groove profile |

|---|---|---|

| Gouging | ||

| Typical gouge | 3,4 kg (7.5 lbs.) per hour | 3,2 mm (.12″) D x 6,8 mm (.26″) W |

Production cut chart

| Material | Thickness inches |

Current amps |

Production cut speed* ipm |

|

|---|---|---|---|---|

| Mild steel | 10 GA | 45 | 181 | |

| 1/4 | 45 | 72 | ||

| 3/8 | 45 | 38 | ||

| 1/2 | 45 | 24 | ||

| 5/8 | 45 | 16 | ||

| Stainless steel | 10 GA | 45 | 134 | |

| 1/4 | 45 | 59 | ||

| 3/8 | 45 | 29 | ||

| 1/2 | 45 | 19 | ||

| 5/8 | 45 | 13 | ||

| Aluminum | 1/8 | 45 | 263 | |

| 1/4 | 45 | 104 | ||

| 3/8 | 45 | 42 | ||

| 1/2 | 45 | 26 | ||

| 5/8 | 45 | 14 | ||

| Material | Thickness mm |

Current amps |

Production cut speed* mm/min |

|---|---|---|---|

| Mild steel | 3 | 45 | 5590 |

| 6 | 45 | 2110 | |

| 10 | 45 | 920 | |

| 12 | 45 | 690 | |

| 16 | 45 | 400 | |

| Stainless steel | 3 | 45 | 4725 |

| 6 | 45 | 1695 | |

| 10 | 45 | 870 | |

| 12 | 45 | 540 | |

| 16 | 45 | 320 | |

| Aluminum | 3 | 45 | 7120 |

| 6 | 45 | 3095 | |

| 10 | 45 | 1015 | |

| 12 | 45 | 745 | |

| 16 | 45 | 340 |

* Production cut speeds are the results of Hypertherm's laboratory testing. For optimum cut performance, actual cutting speeds may vary based on different cutting applications. Refer to the operator manual for more details.

Environmental stewardship is a core value of Hypertherm. Our Powermax products are engineered to meet and exceed global environmental regulations including the RoHS directive.

Environmental stewardship is a core value of Hypertherm. Our Powermax products are engineered to meet and exceed global environmental regulations including the RoHS directive.

Resources

Manuals and documents

Upgrade to the new cartridge consumable platform!

The Hypertherm cartridge consumable platform is a revolutionary change to standard air plasma consumables. Each single-piece cartridge is optimized by process and amperage to ensure performance while dramatically simplifying the parts needed to cut or gouge with plasma.

Torch and cable options

Duramax® Lock torch options

Duramax robotic and mini machine torches, along with Duramax Hyamp® torches are also compatible with the Powermax45 XP.

| Hand torches | Machine torches | Robotic torches | |||||

|---|---|---|---|---|---|---|---|

| Cable length | 75° | 15° | 180° | Mini 180° | 45° | 90° | 180° |

| 4,5 m (15') | 059476* | 059481* | |||||

| 6,1 m (20') | 088164 | 088162 | |||||

| 7,6 m (25') | 088167 | 059482* | 059464* | 059465* | 059466* | ||

| 10,6 m (35') | 088168 | 059483* | |||||

| 15,2 m (50') | 088165 | 088163 | 088169 | 059484* | |||

| 22,8 m (75') | 059475* | 059472* | 059480* | ||||

* Without torch disable switch

Cable options

| Work cables | Control cables | |||||

|---|---|---|---|---|---|---|

| Cable length | Hand clamp | Remote pendant | CNC, spade connector, divided voltage | CNC, spade connector, no divided voltage | RS-485 Serial comm, unterminated | RS-485 Serial comm, D-sub |

| 7,6 m (25′) | 223595 | 128650 | 228350 | 023206 | 223236 | 223239 |

| 15,2 m (50′) | 223596 | 128651 | 228351 | 023279 | 223237 | 223240 |

| 22,8 m (75′) | 223127 | 128652 | ||||

Hypertherm cartridges and adapter upgrade

Cartridge adapter

The cartridge adapter provides an optional upgrade to convert from the use of standard consumables to the new Hypertherm cartridge consumable platform.

The cartridge adapter is designed to work with the following systems and torches. Please note, when using the cartridge on a Duramax® or Duramax® Lock torch with the adapter, no data is transferred from the cartridge to the system for automated process setup or to provide cartridge usage data. That functionality is available for Powermax® SYNC™ systems with SmartSYNC™ torch technology.

|

System |

Torch type |

Adapter part number |

|

Powermax45® XP |

Duramax® Lock hand, machine, and robotic |

|

|

Powermax65® |

Duramax hand, machine, and robotic |

|

|

Powermax85® |

||

|

Powermax105® |

Drag cutting and FineCut® for hand torches

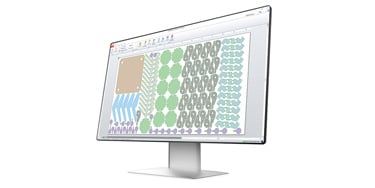

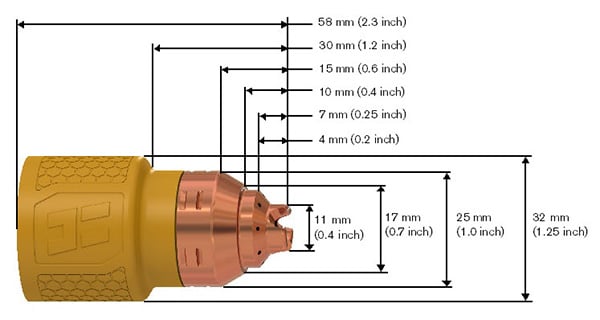

These cartridges have different dimensions as compared to traditional consumables which need to be factored when using cutting templates and guides.

Drag cartridge:

FineCut cartridge:

Mechanized and FineCut® for machine torches

Mechanized cartridges can be used on hand torches if a stand-off is desired.

|

Hypertherm cartridges |

|

|

Process |

Cartridge |

|

45 A |

|

|

FineCut mechanized cutting |

|

|

Ohmic ring kit |

(contains 3 #420580 ohmic rings) |

|

Replaces this stack-up |

||||

|

Shield |

Nozzle | Electrode |

Retaining cap |

Swirl ring |

|

220817 or |

220941 |

220842 or 220777 |

220854 or 220953 |

220857 |

|

220948 or 220955 |

220930 |

220947 |

||