Powermax65 SYNC plasma cutter

For files in additional languages, please go to the Documents Library.

How-to videos (7)

Operator and instruction manuals (15)

.Cut Charts for Powermax45/65/85/105 SYNC (Multilingual) (Revision 4)

.Mechanized Cutting with Powermax45/65/85/105 SYNC (Revision 5)

.Operator Manual for Powermax65/85/105 SYNC (Revision 4)

Showing 6 of 15 documents

Service manuals (3)

Service Replacement Parts for SmartSYNC Torches (Revision 1)

Showing 3 of 3 documents

Specifications

For full specifications, reference the manual.

Cut and gouge capacities

| Cut capacity | Thickness | Cut speed |

|---|---|---|

| Recommended | 20 mm (3/4″) | 500 mm/min (20 ipm) |

| 25 mm (1″) | 250 mm/min (10 ipm) | |

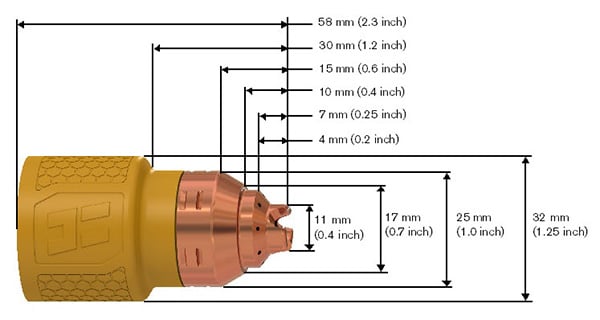

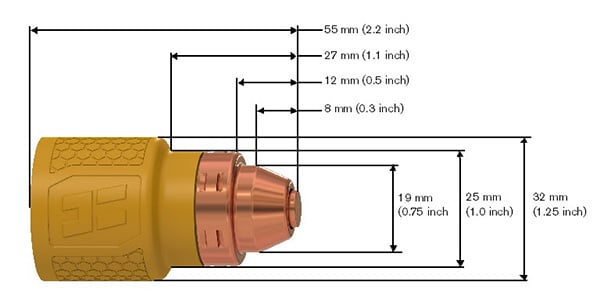

| Severance (hand cutting) | 32 mm (1-1/4″) | 125 mm/min (5 ipm) |

| Pierce* | 16 mm (5/8″) |

*Pierce rating for handheld use or with automatic torch height control

| Gouge capacity | Metal removal rate | Groove profile |

|---|---|---|

| Typical gouge | 4,0 kg (8.8 lbs.) per hour | 2,9 mm D x 6,4 mm W (0.11″ D x 0.25″ W) |

General specifications

Specifications - CSA |

|

|---|---|

|

Input voltages (± 10%) |

200–480 V, 1-PH, 50/60 Hz 200–600 V, 3-PH, 50/60 Hz |

|

Input current @ 9 kW |

200/208/240/480 V, 1-PH 52/50/44/22 A 200/208/240/480/600 V, 3-PH 32/31/27/13/13 A |

|

Output current |

20–65 A |

|

Rated output voltage |

139 VDC |

|

Duty cycle @ 40° C (104° F) |

50% @ 65 A, 230–600 V, 1/3-PH 40% @ 65 A, 200–208 V, 1/3-PH 100% @ 46 A, 230–600 V, 1/3-PH |

|

Open circuit voltage (OCV) |

295 VDC |

|

Weight with 7.6 m (25′) torch |

27.8 kg (61.7 lbs.) |

CSA – for use in the Americas and Asia, except China

Specifications - CE/CCC |

|

|---|---|

|

Input voltages (± 10%) |

380–400 V, 3-PH, 50/60 Hz |

|

Input current @ 9 kW |

380/400 V, 15.5/15 A |

|

Output current |

20–65 A |

|

Rated output voltage |

139 VDC |

|

Duty cycle @ 40° C (104° F) |

50% @ 65 A, 380–400 V, 3-PH 100% @ 46 A, 380–400 V, 3-PH |

|

Open circuit voltage (OCV) |

295 VDC 270 VDC |

|

Weight with 7.6 m (25′) torch |

24.1 kg (52.7 lbs.) |

CE – for use in Europe, Australia & New Zealand - RCM, Serbia, UK – UKCA, Ukraine, and other countries where accepted. CCC – for use in China.

|

Dimensions with handles |

483 mm D; 233 mm W; 430 mm H (19″ D; 9.2″ W; 17″ H) |

|---|---|

|

Gas supply |

Clean, dry, oil-free air or nitrogen |

|

Recommended inlet gas flow rate |

Cutting: 210 I/min @ 5.9 bar (450 scfh, 7.5 scfm @ 85 psi) Gouging: 210 I/min @ 4.8 bar (450 scfh, 7.5 scfm @ 70 psi) |

|

Electrical efficiency |

91.2% |

|

Recyclability |

100% |

|

Warranty |

Power supply: 6-year Torch: 1-year |

Consumables

Please contact an authorized Hypertherm distributor to place your consumables order.

CARTRIDGE-65-Drag-Fine-Hand

CARTRIDGE-65-Mech-standoff-Fine

CARTRIDGE-65-MaxControlRemoval-Mech

CARTRIDGE-65-FlushCut

|

Hypertherm cartridges |

|

|

Process |

FlushCut™ |

| 65 A | |

Accessories

Hypertherm cartridge reader

The Hypertherm cartridge reader provides a simple process for reviewing data stored in Hypertherm cartridges. Data analysis helps customers understand cartridge utilization and identify operator training opportunities.

Powermax EtherCAT Interface for EDGE Connect

The Powermax® EtherCAT® Interface is an all-in-one adapter that allows a digital connection between the Powermax equipment and the EDGE® Connect CNC. This allows faster equipment setup, an intuitive operator interface, and access to real-time diagnostics information.

Robotic torch clamp kit

The robotic torch clamp kit is designed to simplify integration of Powermax® robotic torches on robots. The clamp fits perfectly with the torch dimensions and securely holds the torch during cutting applications.

Cartridge ohmic ring: #428895

The ohmic contact ring clips onto the mechanized cartridge, and connects it via electrical wire to torch height controls (THCs) that support the use of ohmic contact to find the surface of the workpiece before each cut.

Field service bulletins (10)

Cartridge Reader and App | Lecteur de cartouche et application - Powermax65/85/105 SYNC

Heat Shield Kits for T Series, Duramax, Duramax Hyamp Handheld Torches Écran de chaleur des torches manuelles 804230 revision 6

Showing 6 of 10 documents

Technical support

| Resource center |

| Support by product |

| System support |

| Software updates and support |

| Report counterfeit consumables |

| Documents library |

| Training |

| FAQs |

| For educators |

| Tradeshows and events |

| Additional resources |

Useful links

-

Recycling information for Hypertherm customers and recyclers

Learn about Hypertherm's committment to the WEEE Directive in Europe - Elimination, recycling, and reduction of waste is the foundation of a good approach to end-of-life equipment management. Determine the most sustainable path for your system.