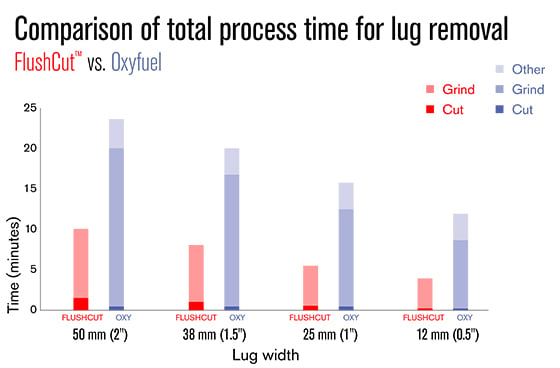

Choosing the Hypertherm® FlushCut process provides a faster, cleaner, and more precise alternative to traditional methods like oxyfuel and carbon arc gouging. Unlike oxyfuel, which struggles with non-ferrous metals and leaves hard to remove slag, plasma delivers smooth, consistent cuts across a wide range of materials and has up to 10 times less heat affected zone (HAZ). Compared to carbon arc, plasma flush cutting produces minimal slag and debris, reducing the need for grinding. With the ability to cut closer to the base metal, and then plasma washing the residual metal away, FlushCut reduces the need for time consuming and labor-intensive grinding thus helping fabricators to improve productivity and cut costs.