Understanding plasma cutting attributes

Knowing plasma cutting capabilities can give you an incredible advantage. Some of this knowledge includes understanding plasma cutting variables, which applications it excels in, cost of operation vs. other technologies, size vs. power, and automation options.

Types of materials plasma can cut

-

Plasma works on electrically conductive metal/workpieces and is commonly used to cut stainless steel, aluminum, mild steel, tool steel, and even titanium.

-

Plasma technology can handle tough workpieces, including rusted or painted surfaces and expanded metal, making the cutting process versatile.

-

Plasma also works on galvanized metal, just ensure there is ventilation when cutting zinc.

Types of plasma cuts

-

Standard cut.

-

Plasma flush cutting is the process of making the cut surface “flush” with the adjacent surface.

-

Plasma bevel cutting aims to make a consistent angled cut that is not perpendicular to the surface.

-

Plasma pierce cutting is where the cut starts in the middle of the metal. An everyday use of pierce cutting is plasma hole cutting.

-

Plasma drag cutting is handheld, where you “drag” the plasma torch along the workpiece.

-

Plasma arc gouging is a technique that removes metal but does not cut through the workpiece, creating a unique profile for weld preparation or repair.

-

Extended-reach plasma cutting uses extended consumables to get into hard-to-reach areas that cannot be accessed by standard consumables. Hypertherm HyAccess™ consumables are a great way to tackle this issue.

-

Plasma skeleton cutting is the process of cutting up and removing the remnants of a metal plate or the “skeleton.”

-

Plasma cast trimming is a method used in foundries and diecasting operations to remove excess material—such as flash, gates, sprues, and runners—from cast metal parts using a plasma cutting torch rather than traditional mechanical tools.

-

Plasma marking can add near-permanent technical information to a workpiece, such as part numbers, barcodes, score lines, and bend indications.

Ideal thickness that plasma cutters can cut to get high quality cuts

The thickness plasma can cut greatly depends on the amperage of the power supply and the torch and consumables. Other significant factors include material type, cutting speed, cutting gases, and part design.

Powermax Systems:

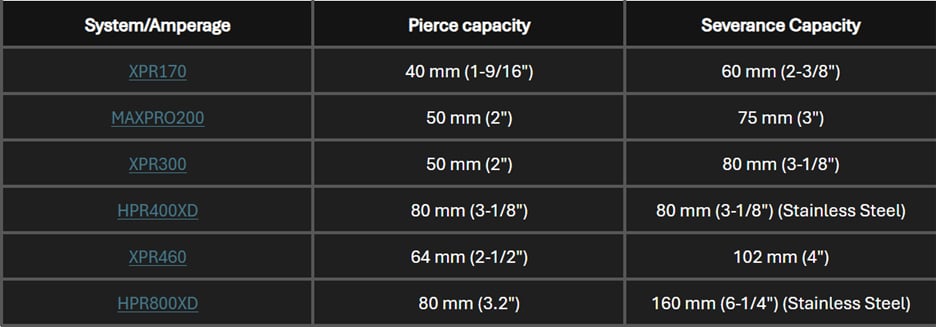

MAXPRO®, HPR®, and XPR® Systems:

How is plasma cut quality measured/determined?

-

Tolerances* in the +/- 0.38 mm to 0.5 mm (+/- 0.015” to 0.020”) range with average edge angularity of 2° to 3° on steel less than 10 mm (3/8”); 1° on 12 mm to 38 mm (1/2” to 1-1/2”) steel; less than 1° on 50 mm (2”) steel.

-

Narrow heat-affected zone, typically less than 0.25 mm (0.010”).

-

Correct choice of process and plasma gases will produce minimal edge hardening, allowing excellent weldability.

-

Relatively clean cuts with smooth torch motion.

-

Minimal dross (resolidified molten metal) on steel, up to rated production capacities.

* Tolerances will vary depending on material type and material thickness, part geometries, and overall design and quality of the cutting system. The tolerances listed here are generally accepted tolerances assuming the use of a good quality cutting table with good motion capabilities. Different cutting tables will provide different outcomes even if equipped with the exact same cutting components.

Productivity: Speed of plasma cutters

-

Plasma provides fast cutting speeds at a variety of thicknesses, from gauge material to over 50 mm (2”). This translates into higher productivity, fewer bottlenecks, better on-time delivery, greater cash flow, and potential for business growth.

-

Above 16 mm (5/8”) mild steel, plasma is faster than a 15kW laser; above 20 mm (3/4”), plasma is faster than a 20kW laser; and above 30 mm (1 3/16”), plasma is faster than a 30kW laser.

-

Plasma cutting is twelve times faster than oxyfuel when cutting thinner materials.

-

Faster than oxyfuel up through 50 mm (2”).

-

Piercing is also faster with plasma than it is with oxyfuel. It can take 30 seconds to pierce 16 mm (5/8″) thick steel with oxyfuel. Plasma takes less than two seconds.

-

Preheating is not required with plasma, as it is with oxyfuel, and there is minimal cool-down time; the workpiece sustains high temperatures for a longer duration with oxyfuel than plasma.

What are different operating costs to consider with plasma cutting systems?

-

Low cost per part on all materials and thickness through 50 mm (2”).

-

Against fiber laser cutting, plasma often costs less per foot/meter for thicker metals due to refined processes and reduced gas consumption.

-

Against oxyfuel, plasma cutting cost less to operate since you do not need to worry about refilling and transporting flammable gas cylinders.

-

Low service and maintenance requirements.

-

Air compressor costs.

-

Consumables. Electrodes, Nozzles, Shield caps, Swirl rings, Retaining caps or just a cartridge.

-

Gas cost for specific cuts.

-

Labor costs for larger operations.

Capital equipment cost vs other cutting technologies.

-

Medium – higher than oxyfuel, lower than laser and waterjet

-

This also varies depending on the size of power supply you need and metal fabrication/machining that you need done.

-

Cutting table for CNC operation.

-

Robots/Cobots for automatic operation.

-

Fume control to ensure a safe environment when mass producing or dealing with certain metals (zinc).

Portability of air plasma cutters (30amp-125amp)

-

Highly portable, lightweight inverter designs on the air plasma systems

-

Today’s systems are designed for good performance on various electricity sources, including generators.

-

Some systems so not need a hook up to compressed air and they include built-in air compressor, such as the Powermax30 AIR.

Automation of plasma cutting

Automation is the future of manufacturing and is also the present. It allows for high frequency optimized production.

-

CNC tables, they are a machine that uses automated technology to cut materials like metal with precision and speed. It can support numerous manufacturing processes, including routing, drilling, oxyfuel cutting, plasma cutting, waterjet cutting, and laser cutting.

-

3D cutting, metal fabricators who want to increase productivity and product throughput choose robot and/or cobot plasma cutting. This innovative solution provides rapid, consistent, and safe cutting and gouging outcomes while reducing secondary operations, all without a significant investment or lengthy learning curve.

Bottom line

Plasma is a fast, efficient, and versatile process for most metal cutting applications. With advanced capabilities like pilot arc technology, CNC and robotic automation, and a variety of cutting techniques, from flush and bevel cuts to gouging and marking, plasma delivers precision, speed, and flexibility. In addition, its ability to cut a wide variety of electrically conductive materials provides outstanding versatility. Whether you're working an array of thicknesses with stainless steel, aluminum, or galvanized metal, plasma excels in both manual and automated environments. A plasma cutter can be used for both mechanized cutting and for portable hand cutting applications, often where other processes cannot be used. Its high productivity, low operating costs, and portability make it an ideal choice for shops looking to boost efficiency and cut quality without compromising on performance.