The [XPR] system boasts of Hypertherm’s True Hole® technology that provides MASI with the ability to easily fabricate bolt ready holes down to a diameter-to-thickness ratio of 1:1.″

MASI

Transportation equipment

Read more

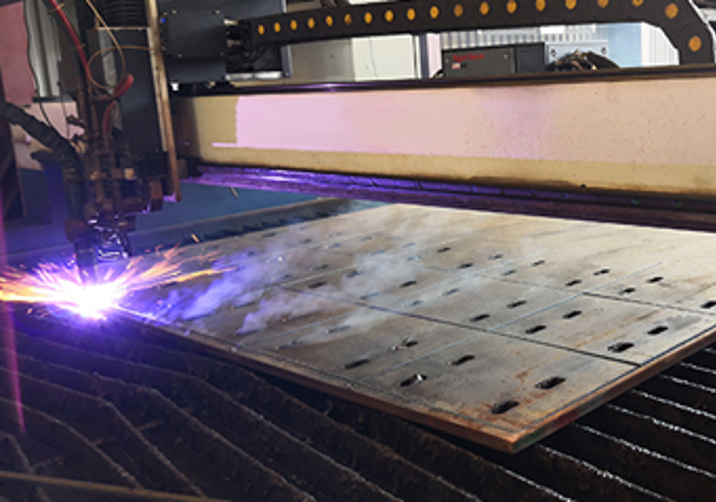

Many fabrication processes require the cutting of holes to bolt two or more pieces or parts together, so hole production is an important part of most cutting operations. Punching, drilling, plasma, waterjet, and laser are all used depending on need and equipment availability. Ideally, fabricators prefer to use a single process for hole cutting – plasma cutting for example – in order to reduce material handling time and minimize production footprint.

Fortunately, today there are ways to nearly eliminate the taper, and the dings and divots, enabling the cutting of “bolt-ready” holes. If using plasma on a mechanized table, an operator can manually change the machine speeds and height control settings and modify the machine codes for a particular hole size, material thickness and power level.

Owners of Hypertherm HyPerformance® HPRXD or XPR® mechanized systems can take advantage of our True Hole® technology, which embeds process expertise and parameters to cut perfect, bolt-ready holes without operator intervention.

Cutting holes by hand using a handheld plasma torch is also possible using tools like a circle cutting guide.

Cutting holes for bolting a cut piece to another plate or part

Cutting multiple holes in a large plate, pipe, or drum for hoses and wire to pass through

Fabricating holes for gauges on an instrument panel