We’re plasma cutting a majority of what was laser cut, with an 80% reduction in laser outsourcing, and we aren’t using oxyfuel as much.”

Precision Flange & Machine, Inc.

Precision machined and manufactured products

Read more

HyPerformance® (HPR) plasma systems deliver superior productivity in X-Y, bevel and robotic cutting and marking applications on metal ranging up to 160 mm (6-1/4″) thick with the HPR800XD. The combination of faster cutting speeds, rapid process cycling, quick changeovers and high reliability boosts throughput while dramatically lowering operating costs.

As time-proven systems, the HPR400XD and HPR800XD are the best suited plasma systems for cutting thick materials including mild steel, stainless steel, and aluminum.

The HPR400XD is capable of piercing and cutting mild steel up to 50 mm (2″) thick and cutting mild steel up to 80 mm (3.2″) when starting on an edge. At 400 amps, the HPR400XD can pierce and cut stainless steel up to 45 mm (1-3/4″) thick and up to 80 mm (3.2″) when starting on an edge. For aluminum, the HPR400XD is capable of piercing and cutting up to 40 mm (1-1/2″) and up to 80 mm (3.2″) edge starting.

The HPR800XD is designed to bring greater thickness capability for stainless steel and aluminum cutting. At 800 amps, the HPR800XD can pierce and cut up to 75 mm (3″) thick stainless steel and aluminum. When edge starting, the system can cut stainless steel and aluminum up to 160 mm (6-1/4″).

Incorporating Hypertherm's proven HyDefinition®, LongLife®, patented PowerPierce®, True Hole®, and True Bevel™ technologies, HyPerformance products offer the ultimate in mild steel cutting performance, as well as excellent stainless steel and aluminum capabilities.

Patented PowerPierce technology extends robust production pierce capability to 50 mm (2″) with 400 amps on mild steel and 75 mm (3″) with 800 amps on stainless steel and aluminum. Combined with a controlled motion process, the technology provides maximum stainless pierce capability up to 75 mm (3″) with 400 amps and 100 mm (4″) with 800 amps.

Liquid cooled shield repels molten material during piercing and cutting to minimize torch damage and improves shield robustness to reduce downtime and lower operating cost.

|

300 pierces at 50 mm (2″) using HPR400XD with PowerPierce technology |

41 pierces at 45 mm (1-3/4″), Competitor A without PowerPierce technology |

Bevel cutting is cutting a part with an edge not perpendicular to the top of the piece. It is typically used to prepare plates or pipes for welding. Bevels can be cut at different angles and configurations, resulting in varying edge profiles.

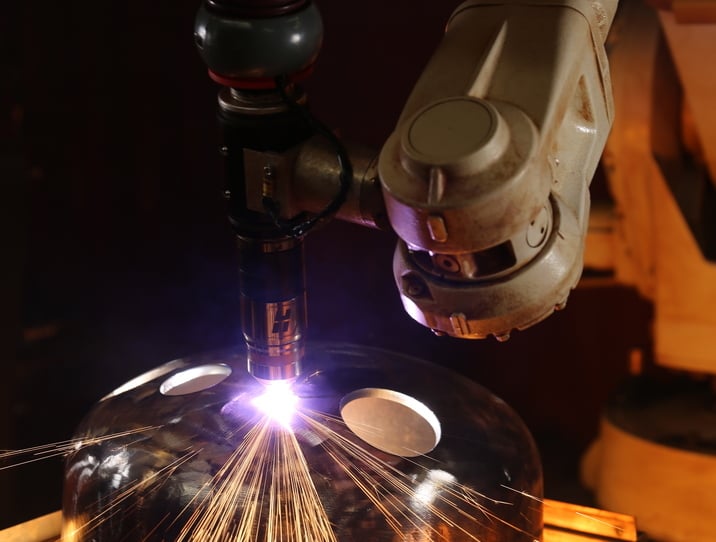

Many fabrication processes require cutting holes to bolt two or more pieces or parts together, so hole production is an important part of most cutting operations. Multiple holes can be cut into a large plate, pipe, or drum with plasma.

Robotic cutting systems support your most complex projects. Combined with robot programming, robotic plasma cutting dramatically improves efficiency by increasing cut speeds, cut quality, and production in low-volume runs — returning hundreds of hours to your business.

The HPR® cartridge from Hypertherm provides a simple, single-piece alternative to traditional plasma consumables that gives you enhanced cut quality while reducing operating costs. For mild steel cutting at 80 A, 130 A, and 260 A, customers will experience longer life, fewer consumable errors, and improved cut quality over life.