Computer numeric controls

The CNC is the main communication interface between the operator and the machine. It tells the other components – and possibly even the operator – what to do.

The CNC:

-

Converts the part program into command signals that will precisely control the direction, speed and cutting processes of the machine

-

Sends and receives signals to control the cutting process, machine functions such as motion, height control movement, and safety components

-

May be used for online part programming or may utilize a part program from offline CAD/CAM software

-

Components include hardware and software

How CNCs work

On large industrial machines, the CNC is basically an advanced industrial computer with internal motion and machine control software and a variety of inputs and outputs to control the drive motors, cutting systems, height controls, and other tools that might be mounted on the cutting machine. It takes its orders from the machine operator and CAM (computer assisted manufacturing) software, converting the orders into perfectly timed electrical signals that control all functionality. Industrial CNCs are designed to be extremely robust, to withstand long term use in dirty, rough, and electrically noisy environments; however, this robustness adds cost and complexity.

Lower cost light industrial tables often use a consumer PC or laptop as the CNC. While these computers, designed for a relatively easy life in clean, temperature-controlled environments, might be expected to have reliability issues in a harsh production environment, they are completely capable of handling the motion and limited input and output requirements on many small machines. If a consumer PC is to be used, the system must be equipped with a modern air plasma cutting system that uses a blowback torch starting technology, which produces a lower level of electrical noise interference. In contrast, older air plasma systems and industrial plasma systems use high frequency, high voltage or capacitive starting that can play havoc with delicate electronics.

When selecting a CNC, you’ll want to look for an easy-to-use interface. While many lower technology machines use a standard office keyboard and mouse to control functionality, the higher-end machines incorporate simple touchscreen controls.

CNC software should be as intuitive as possible. This is often not the case if the CNC software has been repurposed from machining processes such as routing and milling. Select a user interface (CNC software) that’s been designed specifically for cutting tends to be much easier to learn and use on a daily basis.

CNCs play a critical role in the overall success of a cutting machine operation. Ideally, a CNC should provide the user with:

-

Easy operation

-

Consistent, reliable performance

-

Increased productivity

-

Flexible system configurability

-

Accurate motion and process timing

-

Simplified system diagnostics

-

Advanced cut process control

-

Integrated communications to system and tools

-

Regular manufacture software updates to keep pace with the growing needs of the cutting industry

Torch height controls

Using the arc voltage, the torch height control (THC) ensures that the cutting tool doesn’t get too close to or too far away from the work piece.

The THC:

-

Performs initial height sensing (IHS) by starting at the last retract height, lowering to the plate to establish the plate position, and retracting to the pierce height

-

Regulates the height of the cutting tool throughout the cutting process to achieve the required cut quality

-

Extends consumable life by positioning the torch away from molten metal during the pierce and collison detection to stop the cut process

Although not absolutely necessary, a THC is a very worthwhile investment. On a system equipped with a properly functioning height control, you can program and nest hundreds of parts and let the automated system complete the job.

How THCs work

Once programmed, the THC gently touches the surface of the material, and then retracts to the proper pierce height. After starting a pierce, the THC will tell the torch to wait a second or two to allow for a full pierce, then have it move down to cut height, which is critical to cut quality. If the torch is too low, you risk a collision with the plate; too high and you’ll get a kerf that’s too wide, as well as increased edge angularity, dross, and warpage. Once the X and Y motion get up to speed (after the height control delay timer times out) the arc voltage feedback control takes over to maintain the proper torch-to-work distance.

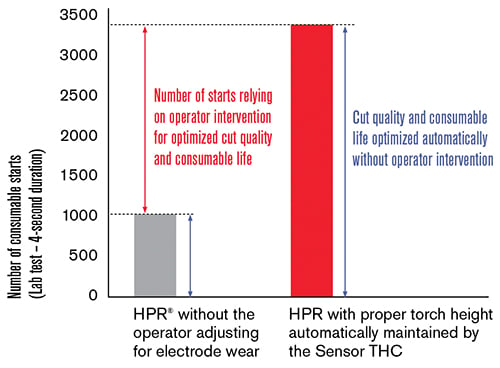

Number of consumable starts with < 0.25 mm (0.010”) deviation from proper cut height without operator intervention (130 A) 12 mm (1/2”) mild steel

With traditional THCs, the operator must periodically adjust the set arc voltage to ensure proper cut height. For increased productivity and profitability, look for an intelligent THC system that automatically adjusts for electrode wear. Some THC systems offer arc voltage sampling to track the progressive consumable wear. By continuously monitoring the arc voltage after each pierce, the value of the set arc voltage value can automatically be adjusted to consistently maintain the proper cut height over the life of the consumables, without additional operator input. This results in achieving optimized cut quality and the maximum consumable life saving both time and money.