MASTER CORTE successfully meets growing demand by leveraging plasma and laser technologies for thick and thin metal cutting

Together, industrial cutting leaders Hypertherm Associates and Messer Cutting Systems deliver a competitive edge in speed and quality

Combined business impact

-

Maximize up time by assigning the right tool to the right job

-

Expand material versatility, allowing for a broader range of customer orders

-

Reduce production bottlenecks as each system handled its optimal workload

Company overview

MASTER CORTE, located in São Carlos, São Paulo, Brazil, specializes in the service and manufacturing of parts using advanced cutting technologies. Operating across various sectors, including civil construction, white line, yellow line, and automotive, MASTER CORTE delivers the best possible cutting solutions to its customers. The company uses processes such as plasma cutting, laser cutting, bending, MIG/TIG welding, and electrostatic painting.

Challenge: MASTER CORTE faced demand for faster turnaround times

MASTER CORTE, a mid-sized fabrication company specializing in custom metal parts, offers high-quality services to customers and is equipped with high-tech machinery capable of cutting sheets up to 80mm (3.15 in) for carbon steel and 38mm (1.5 in) for stainless steel and aluminum. The company faced increased pressure to deliver faster turnaround times while maintaining high cut quality across a variety of materials and thicknesses. Their existing cutting process flow was struggling to keep up with demand, especially when switching between thick mild steel and thin stainless steel or aluminum.

The company desired a solution that could:

-

Handle a wide range of materials and thicknesses

-

Deliver high-speed, high-precision cuts

-

Reduce consumables and maintenance costs

- Integrate easily into their existing workflow

Solution: MASTER CORTE implemented two complementary cutting technologies

MASTER CORTE gained the best of two worlds by implementing the Hypertherm XPR300® plasma system and Messer FiberBlade V fiber laser system and leveraging the strengths of both technologies:

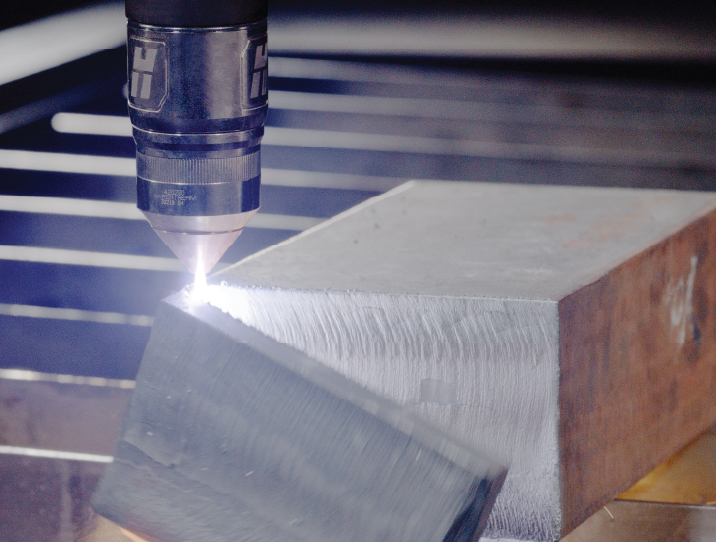

XPR300: powerful, high-quality cuts on thicker metals

The Hypertherm XPR300 power significantly reduces operational costs, particularly in rework, enabling MASTER CORTE to efficiently achieve high-volume cutting with thick materials. The XPR series of plasma systems provides high-speed, accurate, and weld-ready cuts and bevels in thick metal, with virtually no rework, ensuring low operational costs while maintaining high customer productivity and quality.

The Hypertherm XPR300 offers:

-

X-Definition™ weld-ready cut quality: Delivers accurate, ISO range 2 and 3 cuts on mild steel, and with industry-exclusive VWI (vented water injection) technology, provides world-class cut quality on stainless steel and aluminum

-

Faster cutting speeds: Up to 12% faster than previous plasma systems

-

Extended consumable life: Up to 3x longer life due to Arc Response Technology™

-

Lower operating costs: Uses oxygen across the power range, reducing the need for expensive gases

-

Ease of use: Features like EasyConnect™ torch leads and QuickLock™ electrodes simplify operation and maintenance

-

Advanced diagnostics: Built-in sensors and monitoring reduce downtime and improve system optimization

Ana Paula Crnkovic, CEO and owner of MASTER CORTE, emphasizes the importance of providing top-notch equipment to ensure exceptional service performance. Among the numerous equipment options available, Hypertherm plasma stood out for cut quality and reliability.

The Hypertherm XPR300 is a machine that brings a lot of reliability and cutting quality without rework

Ana Paula Crnkovic

CEO and owner of MASTER CORTE

Hugo Crnkovic, partner and owner of MASTER CORTE, noted the Messer TerraBlade 4.0, equipped with a Hypertherm XPR300 power source and a VWI gas console, excels at cutting carbon steel from 10mm to 50mm, and stainless steel and aluminum up to 38mm, using the N2H2O process. The plasma cutter delivers high reliability and cutting quality without rework, making it a robust solution that aligns productivity with quality.

MASTER CORTE also utilized the Messer FiberBlade V, a 6,000W laser cutting machine for high-speed, high-precision cutting of thin to medium-thickness metals.

Plasma and fiber laser cutting solutions working side by side

By leveraging the unique strengths of each technology, the combination of plasma and laser cutting technologies has proven highly effective, especially when processing a wide range of thicknesses. XPR X-Definition plasma cutting delivers lower operating costs, higher cutting speeds, and excellent cut and bevel quality, especially for metal thicknesses greater than 25mm (1 inch). Utilizing XPR-plasma capabilities in thick metal, combined with fiber lasers' undeniable speed and accuracy in thinner metals, MASTER CORTE delivers superior cutting solutions at reduced cost.

Successfully meeting high demand

With a growing demand for cutting thicknesses from 10mm to 32mm (0.39 to 1.26 inches), plasma cutting remains a viable and cost-effective solution. MASTER CORTE's strategic use of both plasma and laser cutting technologies ensures optimal performance and quality, delivering the best possible cutting solutions to customers.

MASTER CORTE continues to innovate and lead in the cutting technology industry, delivering high-quality, efficient, and cost-effective solutions to meet diverse customer needs.