Understand common bevel challenges

Beveling by trial and error

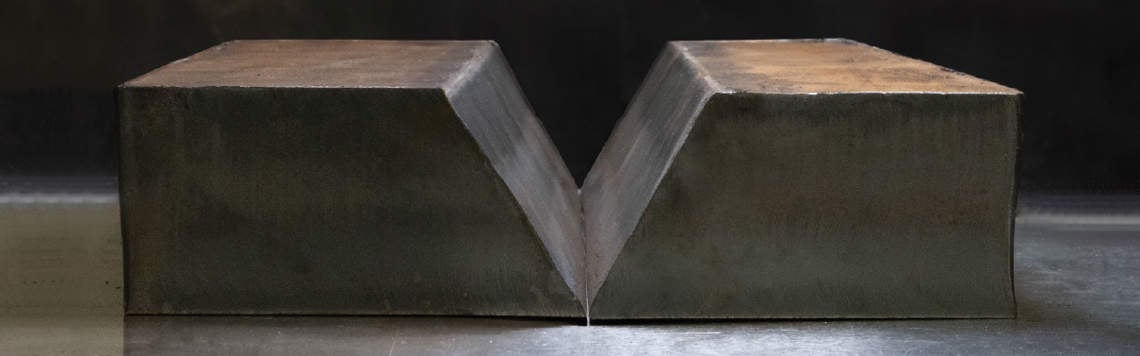

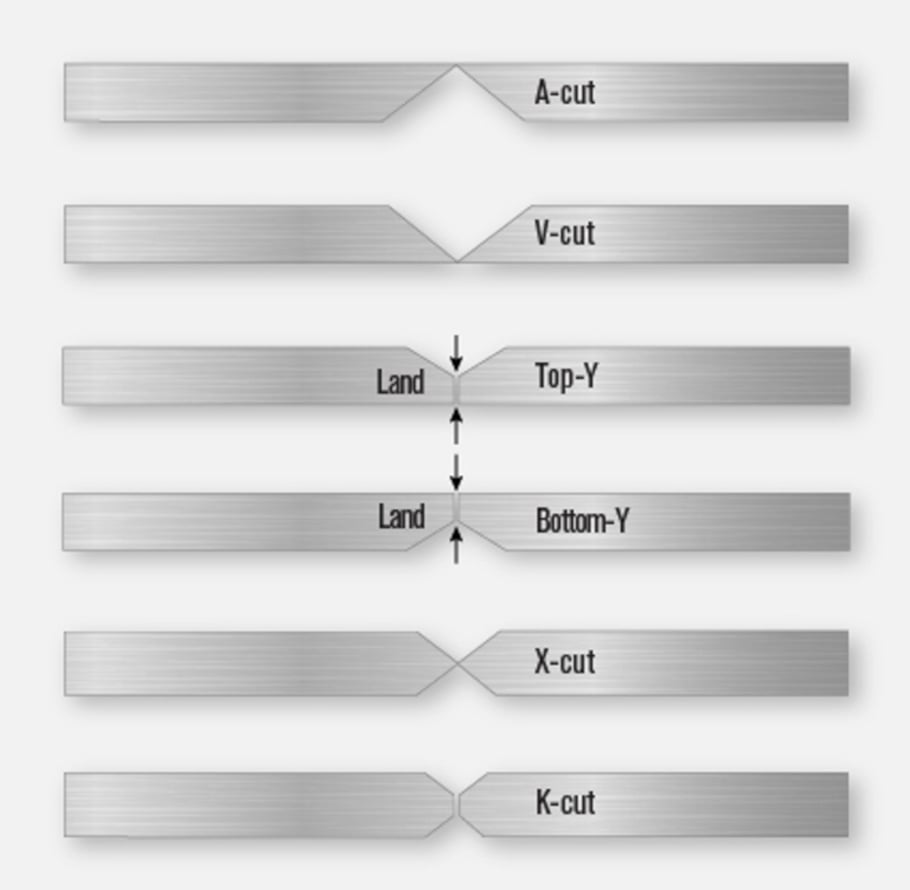

Bevel jobs are time-consuming, no matter how you do them. While Oxyfuel is easy to set up and predictable, the cutting time is long. This produces more heat affected zone (HAZ) due to slow travel and more heat input into the part as a result. With plasma, even if the bevel head is accurate, the cut can be complicated requiring off-table beveling or machine grinding.

The typical beveling process is often inefficient and costly

-

An operator sets up a plate, loads the part program, and runs a test cut

-

The part is examined and measured to determine if it’s to specification

-

If not to specification, the operator calls in a programmer to examine the part and adjust the program, dialing in the angle, land size, or part dimensions

-

The programmer sends the revised program, and the operator sets up another trial run

- This process continues until the bevel part is correct, often several rounds

A more complex part or nest of a different thickness, angle, or bevel type can easily take three or four hours to get it right. Operators undergo a trial-and-error setup for each new combination, disrupting production, causing unproductive labor time, and increasing scrap.