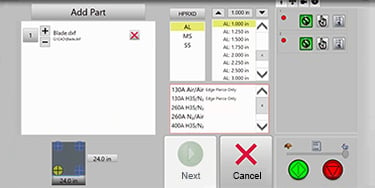

Combining Plazmax’s proprietary bevel head and Hypertherm True Bevel technology, the machine allows the production team to skip the time-consuming task of dialing in bevel cutting parameters, and creates accurate and consistent beveled edges in a single step.

GH Engineering Ltd

Metal fabricator

Read more