Thanks to these automatic machines we are also able to increase the capacity to our desired target of 300 tons of production per month.”

EXCON

Structural steel

Read more

Whether cutting steel girders for holding up bridges or steel beams for holding up buildings, Hypertherm plasma solutions are hard at work in structural steel plants around the world.

Hypertherm solutions help improve productivity, reduce costs, reduce floorspace and improve operator’s safety. Replacement of commonly used oxyfuel torches to plasma allows quantifiable gains in cut quality, speed of cut, and reductions in setup times, material distortion and fuel gas consumption.

Structural steel fabricators around the world use XPR™ plasma systems with X-Definition® technology to improve cut quality, streamline operations, and increase market share by increasing their business opportunities.

A single Hypertherm HyPerformance® plasma system in an automated cell can replace up to seven individual fabricating machines used for tasks like beveling, sawing, marking, coping, drilling, punching, and shearing.

Handheld plasma cutting systems are widely used in this industry as well when design changes or last-minute fit-up is necessary to keep the job on schedule. FlushCut™ consumables are perfect for creating rat holes and removing flanges with minimal secondary grinding.

Cutting plate to size

Piercing holes in steel plate

Cutting rods and tubes to length

Cutting structural beams, baseplates, flanges, gussets, frames, and girders

Coping beams and structural tube so on-site fit-up is perfect

Automated plate edge finishing of A,V, Y and K bevel angles for weld preparation

Bevel cutting is cutting a part with an edge not perpendicular to the top of the piece. It is typically used to prepare plates or pipes for welding. Bevels can be cut at different angles and configurations, resulting in varying edge profiles.

FlushCut® consumables for Powermax® systems allow easy removal of protrusions, welded attachments, bolts, and fixtures from metal surfaces without cutting into the base material.

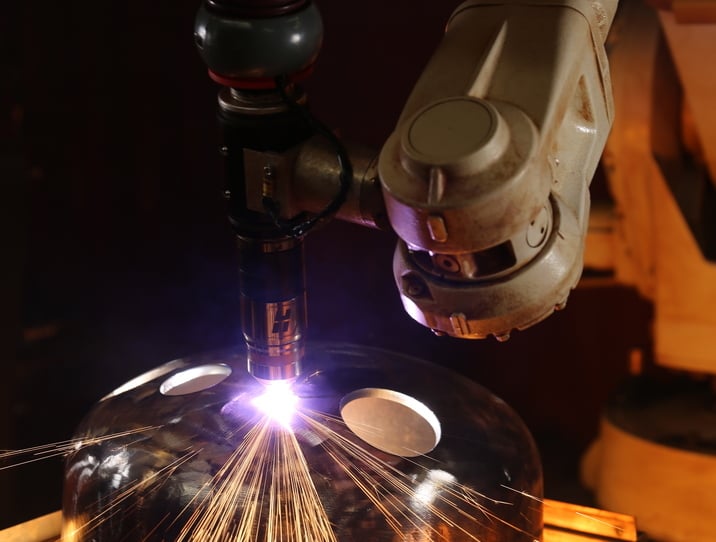

Many fabrication processes require cutting holes to bolt two or more pieces or parts together, so hole production is an important part of most cutting operations. Multiple holes can be cut into a large plate, pipe, or drum with plasma.

Flush cutting with Powermax® plasma systems lets you cut closer to base materials than ever before, reducing costly, time consuming secondary operations. Cleaner cuts with less damage to the base metal saves costs in reusable temporary attachments.

Robotic cutting systems support your most complex projects. Combined with robot programming, robotic plasma cutting dramatically improves efficiency by increasing cut speeds, cut quality, and production in low-volume runs — returning hundreds of hours to your business.

CAM software helps drive the manufacturing process. CAD/CAM nesting software is typically used for programming mechanized flat plate cutting, offering fabricators and manufacturers a single software solution for all of their profile cutting needs. This combination solution provides all of the necessary functionality to complete the job, from CAD concept, to part preparation, to nesting, to numeric code output.