Pipe and pipelines

When it comes to pipes and pipelines, Hypertherm systems are used both in the mill and in the field.

Overview

Larger mechanized plasma systems are used in mills to cut pipe to size and to add holes and notches. In the field, pipeline workers use Powermax® air plasma to cut pipe, gouge out welds for repair, and create beveled edges for tighter fit-ups. Hypertherm air plasma systems can be used with a handheld torch, or with a mechanized air plasma torch on automated or manual pipe cutting and beveling tools. With automated systems, solutions such as ProNest® software can simplify the layout of large pipe sections and automatically calculate cuts and transitions.

Plasma offers significant advantages over other pipe cutting methods such as oxyfuel, carbon arc, and grinding. It’s safer, because it requires no flammable gas canisters, and the process doesn’t create airborne metal shards or swarf that might cause operator injury. In addition, plasma offers greater control and precision than alternative methods, and is also faster, since pre-heating isn’t required.

Typical uses include:

-

Pipe fabrication

-

Weld prep beveled edges for tighter fit-up and welding of pipe sections

-

Gouging welded joints prior to dismantling or rewelding

-

Pipe fit-up

-

Pipeline repair

Explore pipe and pipeline solutions

Plasma bevel cutting

Bevel cutting is cutting a part with an edge not perpendicular to the top of the piece. It is typically used to prepare plates or pipes for welding. Bevels can be cut at different angles and configurations, resulting in varying edge profiles.

Plasma gouging

Plasma gouging – removing metal using a plasma arc – is similar to plasma cutting. A plasma arc between the torch and the workpiece melts the metal, and a gas jet blows away the molten material.

Extended reach cutting

Hypertherm’s HyAccess® extended reach consumables give users extra reach when plasma cutting or gouging in hard to access or confined spaces, and are designed for use with Powermax air plasma systems.

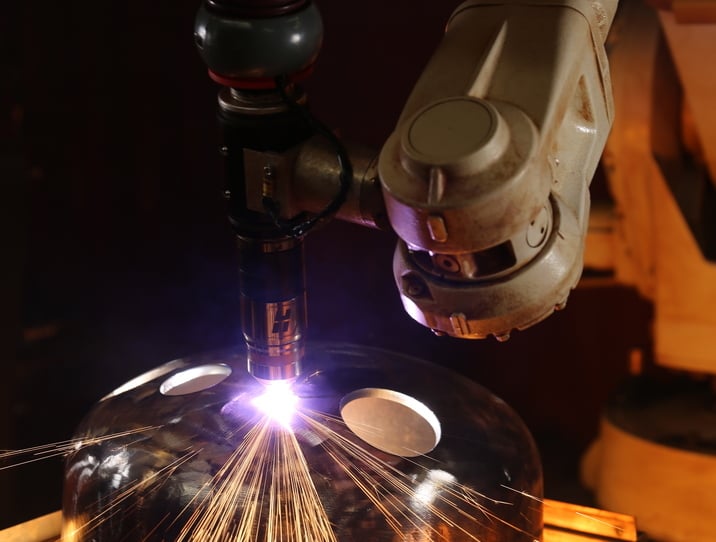

Robotic plasma cutting

Robotic cutting systems support your most complex projects. Combined with robot programming, robotic plasma cutting dramatically improves efficiency by increasing cut speeds, cut quality, and production in low-volume runs — returning hundreds of hours to your business.

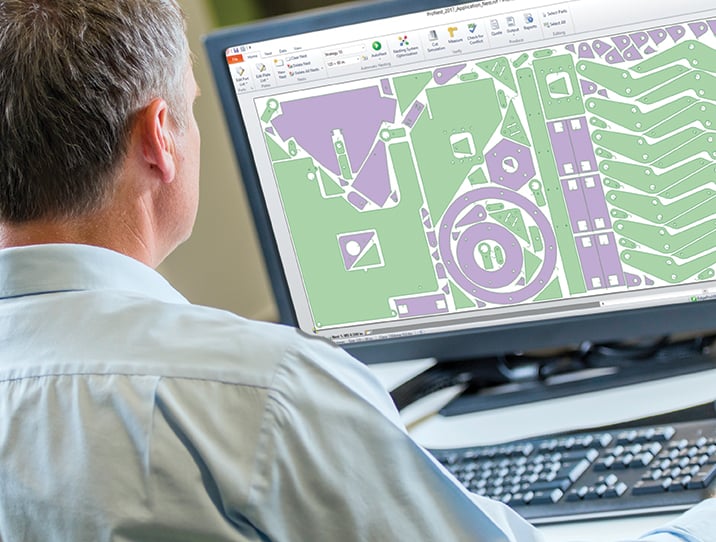

CAM programming

CAM software helps drive the manufacturing process. CAD/CAM nesting software is typically used for programming mechanized flat plate cutting, offering fabricators and manufacturers a single software solution for all of their profile cutting needs. This combination solution provides all of the necessary functionality to complete the job, from CAD concept, to part preparation, to nesting, to numeric code output.

CNC programming

With built in cutting expertise, Hypertherm’s Computer Numeric Control solutions provide consistent product performance with our easy to learn and use Phoenix® software so operators make the optimal cut, every time.