The [XPR] system boasts of Hypertherm’s True Hole® technology that provides MASI with the ability to easily fabricate bolt ready holes down to a diameter-to-thickness ratio of 1:1.″

MASI

Transportation equipment

Read more

Hypertherm plasma, laser, and waterjet systems are behind the fabrication of planes, trains, automobiles, and everything in between.

Our automated systems are used to manufacture semi-trailers, trucks, trailers, buses, locomotives, and rolling stock. In fact, just about any vehicle used to transport people or goods. Our handheld systems are put to work every day in garages and rail yards where fleets and trains are maintained and repaired.

Heavy truck maintenance

Kingpin resetting

Cutting steel piping

Exhaust system replacement

Railcar platform repair

Vent installation

Replacement and repair of log-guards, load rails, truck beds, bumpers, trailer bodies, and frames

Automated plate edge finishing of A,V, Y and K bevel angles for weld preparation

Bevel cutting is cutting a part with an edge not perpendicular to the top of the piece. It is typically used to prepare plates or pipes for welding. Bevels can be cut at different angles and configurations, resulting in varying edge profiles.

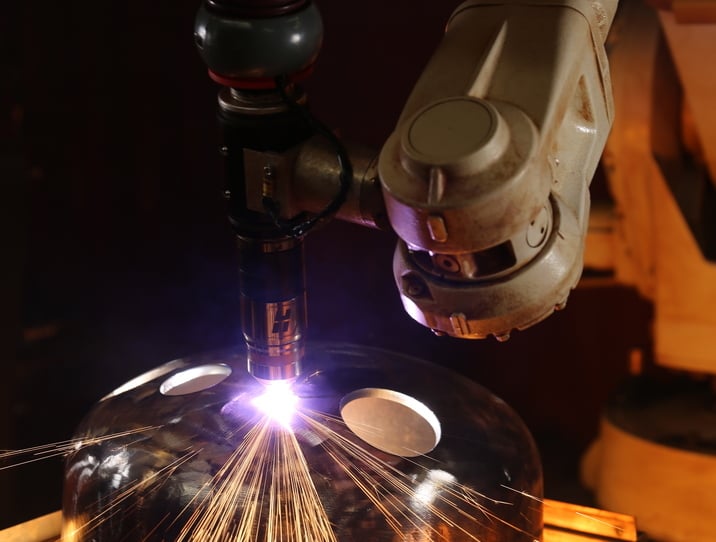

Robotic cutting systems support your most complex projects. Combined with robot programming, robotic plasma cutting dramatically improves efficiency by increasing cut speeds, cut quality, and production in low-volume runs — returning hundreds of hours to your business.

Hypertherm’s HyAccess® extended reach consumables give users extra reach when plasma cutting or gouging in hard to access or confined spaces, and are designed for use with Powermax air plasma systems.

CAM software helps drive the manufacturing process. CAD/CAM nesting software is typically used for programming mechanized flat plate cutting, offering fabricators and manufacturers a single software solution for all of their profile cutting needs. This combination solution provides all of the necessary functionality to complete the job, from CAD concept, to part preparation, to nesting, to numeric code output.

Offline programming solutions to maximize robot productivity on high-mix, low-volume production runs. Reduce programming time, easily program parts of varying complexities, and eliminate the robot downtime associated with manual or teach pendant programming.

Flush cutting with Powermax® plasma systems lets you cut closer to base materials than ever before, reducing costly, time consuming secondary operations. Cleaner cuts with less damage to the base metal saves costs in reusable temporary attachments.