Mining

Overview

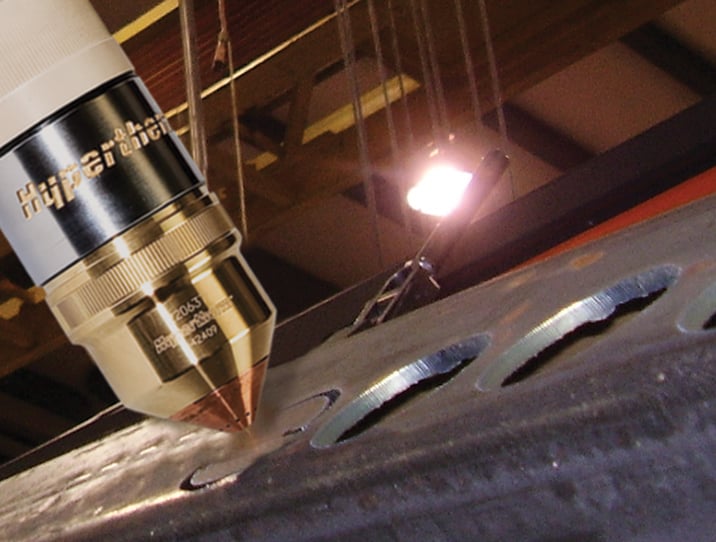

Hypertherm HyPerformance® plasma is routinely used in the manufacture of heavy mining equipment because of its ability to cut heavy steel at high speeds, and there is virtually no need for secondary operations. While HyPerformance plasma is preferred outside the mines, when it comes time to head underground, mining companies turn to another Hypertherm product: Powermax® air plasma. The combination of durability, portability, reliability, and ease of use makes these systems an ideal cutting solution for harsh mining environments.

Typical uses include:

-

Gouging out welds prior to repairing trucks and loaders

-

Pipe fabrication and repair

-

Parts fabrication (e.g., angle irons, pipe supports, hanging brackets, etc.)

-

Repair of heavy equipment such as loaders, shovels, graders, bulldozers, truck beds, and utility vehicles

-

Automated plate edge finishing of A, V, Y and K bevel angles for weld preparation

Explore mining solutions

Plasma bevel cutting

Bevel cutting is cutting a part with an edge not perpendicular to the top of the piece. It is typically used to prepare plates or pipes for welding. Bevels can be cut at different angles and configurations, resulting in varying edge profiles.

Plasma flush cutting

FlushCut® consumables for Powermax® systems allow easy removal of protrusions, welded attachments, bolts, and fixtures from metal surfaces without cutting into the base material.

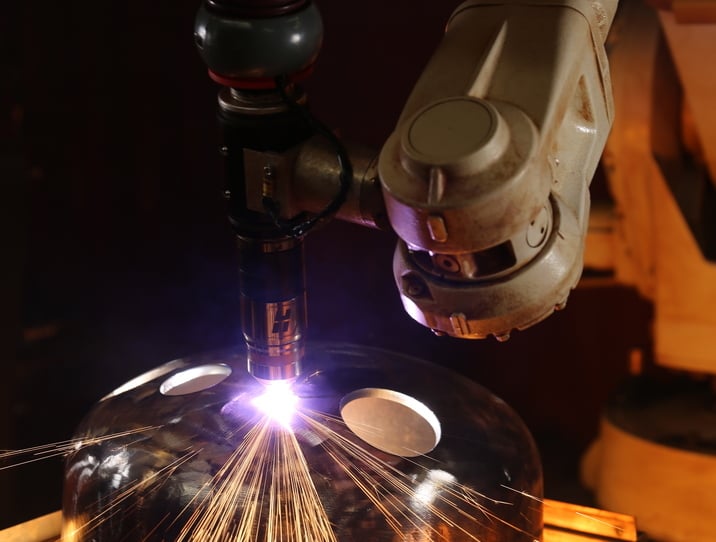

Robotic plasma cutting

Robotic cutting systems support your most complex projects. Combined with robot programming, robotic plasma cutting dramatically improves efficiency by increasing cut speeds, cut quality, and production in low-volume runs — returning hundreds of hours to your business.

Plasma gouging

Plasma gouging – removing metal using a plasma arc – is similar to plasma cutting. A plasma arc between the torch and the workpiece melts the metal, and a gas jet blows away the molten material.

Plasma hole cutting

Many fabrication processes require cutting holes to bolt two or more pieces or parts together, so hole production is an important part of most cutting operations. Multiple holes can be cut into a large plate, pipe, or drum with plasma.

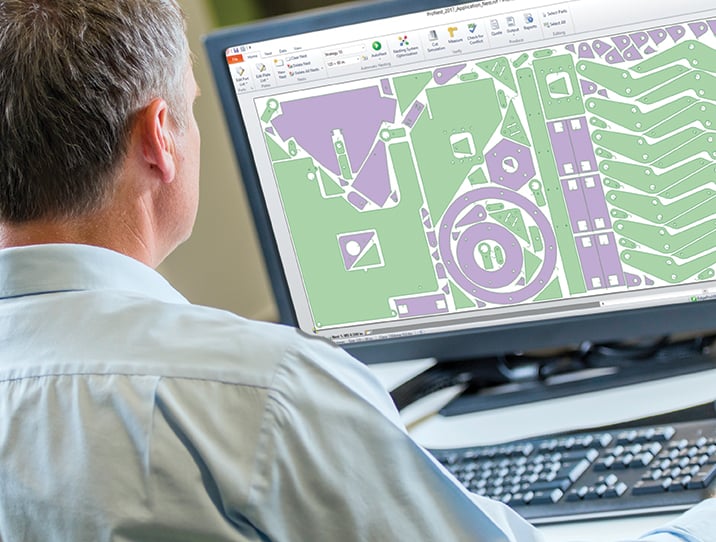

CAM programming

CAM software helps drive the manufacturing process. CAD/CAM nesting software is typically used for programming mechanized flat plate cutting, offering fabricators and manufacturers a single software solution for all of their profile cutting needs. This combination solution provides all of the necessary functionality to complete the job, from CAD concept, to part preparation, to nesting, to numeric code output.

CNC programming

With built in cutting expertise, Hypertherm’s Computer Numeric Control solutions provide consistent product performance with our easy to learn and use Phoenix® software so operators make the optimal cut, every time.