Plasma Bevel Cutting FAQs

What is a bevel cut?

A bevel cut is an angled cut made on the edge of a metal and an enabler for welding. Unlike a straight cut perpendicular to the surface, a bevel cut is made at an angle other than 90° degrees. This type of cut is often used in carpentry, woodworking, and metalworking to create joints, decorative edges, or to fit pieces together more precisely.

Why do metal fabricators need to cut bevels?

In metal fabrication, beveling is commonly used to prepare the edges of metal for welding, increasing the surface area for the weld and leading to stronger and more durable joints.

What are the different ways to cut a bevel in metal?

Bevel cuts can be made using various methods, including plasma, laser, oxyfuel, and waterjet. Each method has advantages and is chosen based on the project's requirements.

Traditional bevel cutting methods:

Traditional beveling methods, like hand grinding and flame cutting, require significant manual effort, making them labor-intensive and inefficient for large-scale operations. These methods often expose workers to hazardous fumes, flying debris, and sharp edges, increasing the risk of injury. Additionally, manual techniques lack precision, leading to inconsistent bevel angles and poor cut quality, which can affect the integrity of welded joints and final fabrication. Automated beveling solutions offer a safer and more precise alternative.

Plasma beveling

Plasma beveling is a cutting process that creates angled edges on metal parts, typically in preparation for welding. This technique involves using a plasma torch to cut the metal at various angles, resulting in different edge profiles such as V, A, X, Y, and K-type bevels.

Key benefits of plasma beveling include:

High precision and consistency: Modern plasma process solutions, such as Hypertherm® True Bevel™ technology, offer accurate and repeatable cuts.

Efficiency: Plasma beveling can be faster and more cost-effective than traditional methods. Plasma cutting requires less gas consumption than oxyfuel and lower maintenance costs than fiber laser, making it more economical over time.

Reduced need for secondary operations: The high-quality cuts often eliminate the need for additional grinding or finishing.

Laser beveling

Laser beveling is a specialized laser cutting technique used to create angled edges on materials. This process enhances the versatility and precision of traditional laser cutting, allowing the production of complex shapes and beveled surfaces.

Key aspects of laser beveling include:

Precision: Laser beveling offers high accuracy, making it suitable for industries like automotive, aerospace, and metal manufacturing.

Efficiency: The process is faster and more automated than traditional beveling methods. However, some laser processes such as using nitrogen can prove costly.

Versatility: It can create various bevel shapes, such as V, Y, X, and U, essential for welding and assembly.

Oxyfuel beveling

Oxyfuel beveling is a cutting process that combines fuel gas and oxygen to create angled edges on thick metal plates. This method is particularly effective for cutting mild and low-alloy steel, especially when the material thickness exceeds 50 mm (2").

Key aspects of oxyfuel beveling include:

Efficiency: It is one of the most cost-effective methods for cutting thick steel plates. However, using Oxyfuel to bevel can lead to significant secondary operations and increased costs.

Versatility: Can produce various bevel shapes such as I, V, X, Y, and K.

Waterjet beveling

Waterjet beveling is a cutting process that uses high-pressure water mixed with abrasive materials to create angled edges on various materials, including metals, composites, and stone. This technique is known for its precision and versatility, making it suitable for complex shapes and detailed parts.

Key benefits of waterjet beveling include:

High-quality cuts: Produces smooth, clean edges that often eliminate the need for secondary finishing.

Minimal kerf: The narrow cutting width allows for intricate designs and efficient material usage.

No thermal damage: Unlike other cutting methods, waterjet beveling does not generate heat, preventing material distortion and changes in the material’s properties.

What is off-table beveling?

Off-table beveling refers to beveling metal parts outside a traditional CNC cutting table setup. This method is beneficial when dealing with large or irregularly shaped workpieces that cannot fit on a standard cutting table.

Key Benefits of Off Table Beveling

-

Flexibility: Allows beveling and cutting in various locations inside the shop and the field.

-

Efficiency: Reduces bottlenecks in production by enabling beveling without needing a dedicated CNC table.

Scrap metal reduction: Off table beveling allows for better plate utilization as you can bevel after well-nested parts are cut.

-

Improved quality: Systems like the DC-IV MAX from Bug-O Systems provide precise, repeatable bevels with minimal setup time.

-

Reduced material handling: Lightweight and portable equipment can be brought directly to the workpiece, minimizing the need for moving heavy materials.

What is robotic off-table beveling?

Robotic beveling is an advanced cutting technique that uses robotic systems to create angled edges on materials. This method enhances precision, efficiency, and consistency in beveling processes.

Key features of robotic beveling

Automation: Robots can handle the entire beveling process, from picking up the material to placing it after beveling. This reduces manual labor and increases productivity.

Flexibility: Robotic systems use collaborative robots with multiple axes of motion, allowing for complex bevel shapes and angles.

Consistency: Robots ensure uniform bevels across multiple parts, maintaining high-quality standards.

Safety: Enclosed safety guard systems prevent operator harm and tampering, ensuring a safe working environment.

Why is plasma the best technology for metal beveling?

Plasma technology is considered one of the best methods for metal beveling due to several key advantages:

Precision and accuracy: Modern plasma systems, especially those with high-definition capabilities, offer highly precise cuts with minimal taper angles. This precision is crucial for creating accurate bevels that fit perfectly for welding and assembly.

Speed and efficiency: Plasma beveling is significantly faster than traditional methods like oxyfuel cutting. This increased speed translates to higher productivity and reduced lead times.

Versatility: Plasma technology can cut through various electrically conductive materials, including stainless steel, aluminum, and mild steel. It can also create bevel shapes such as V, Y, X, and K.

Quality of cuts: The cuts produced by plasma beveling are clean and smooth, often eliminating the need for secondary finishing processes. This high-quality edge is essential for ensuring strong welds and reducing preparation time.

Automation and integration: Modern plasma beveling systems can be integrated with CNC machines, allowing for automated and highly repeatable cuts. This integration enhances consistency and reduces the need for manual intervention.

What are the five types of plasma bevel cuts?

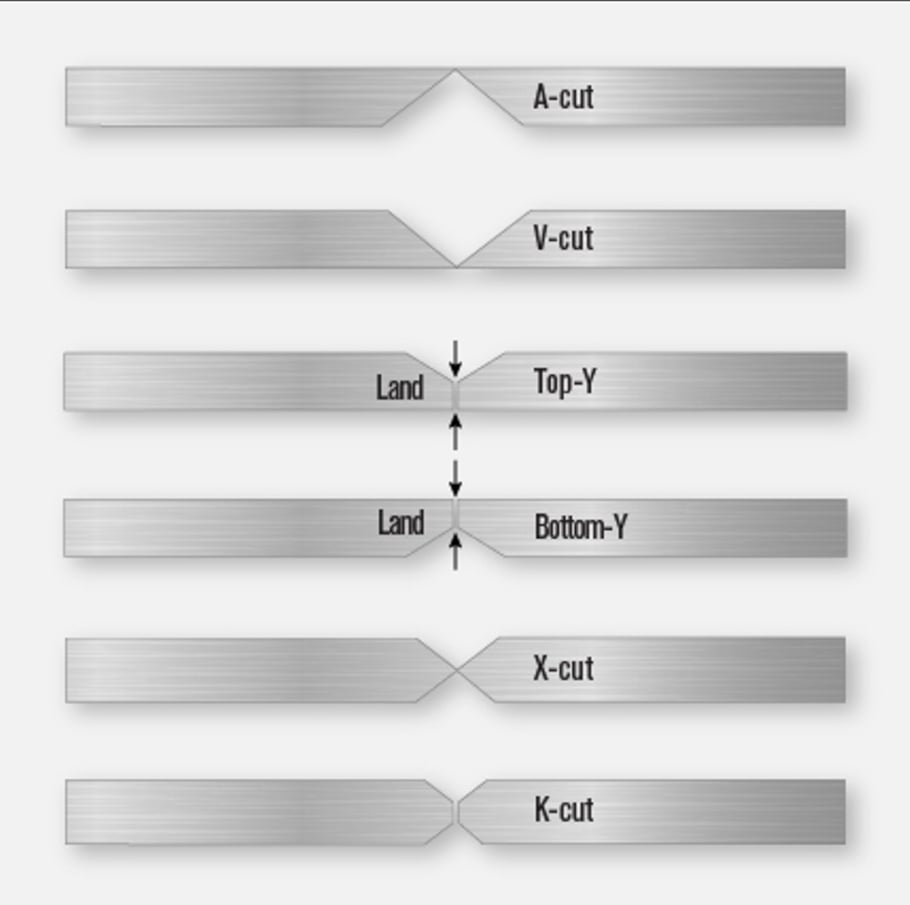

The five types of plasma bevel cuts are A, K, V, X, and Y. Each type has unique characteristics and applications:

A bevel: This is the most common type of bevel cut. It requires a single torch pass and leaves a cut edge that protrudes on top. It's often used for simple welding preparations.

K bevel: The most complex profile requires three passes of the torch. It combines a top Y and a bottom Y, leaving a vertical land in the middle of the cut. This type is used for creating strong, multi-pass welds.

V bevel: A V bevel is essentially an inverted A bevel, requiring one torch pass. The cut protrudes on the bottom edge. It's used for welding joints that need full penetration.

X bevel: A combination of A and V bevels, where the mid-point of the two cuts meets in the middle of the plate, forming an X shape. This cut requires two torch passes. It's used for creating joints that need balanced strength on both sides.

Y bevel: Comes in two varieties ― top Y and bottom Y. The top Y has a V bevel that doesn't extend through the plate, leaving a vertical face at the bottom. The bottom Y is the opposite, with the vertical face at the top and an A bevel at the bottom. These cuts are used for specific welding applications where partial penetration is required.

Beyond a plasma cutter, what else do I need to get good bevel cuts?

To achieve high-quality bevel cuts with a plasma cutter, you'll need additional tools and equipment:

CNC machine: Integrating your plasma cutter with a CNC (Computer Numerical Control) machine ensures precision and repeatability in your cuts.

THC machine: A THC (Torch Height Control) machine is crucial in plasma bevel cutting, maintaining the optimal distance between the plasma torch and the material being cut. This ensures consistent cut quality and precision, especially when dealing with angled cuts.

Modern high-definition technology: Hypertherm® SureCut™ technology uses software to automatically embed advanced cutting capabilities, including True Bevel™ technology, into the plasma cutting process. True Bevel automatically applies improved bevel angle and cut sequence, increasing accuracy and quality consistency.

Beveling software: Specialized software helps program the desired bevel angles and paths, making the process more efficient and accurate.

Clamps and fixtures: These are essential for securing the material in place and preventing movement during the cutting process.

Measuring tools: Accurate measurements are crucial. Tools like protractors, digital angle finders, and rulers help ensure precise angle settings.

Safety equipment: Always prioritize safety. Use safety glasses, gloves, and appropriate protective clothing to safeguard against sparks and debris.

Consumables: Keep a stock of consumables like nozzles, electrodes, and shields. These parts wear out over time and need regular replacement to maintain cutting quality.

Air filtration system: A good air filtration system helps remove dust and fumes generated during cutting, ensuring a clean and safe working environment.

Have more questions?

Ask a Cutting Pro