The quality of the XPR300® cut is the very best that I’ve seen. It’s helping us to expand into other sectors such as agricultural, aeronautical, architectural, structural, and energy.”

Lyman-Morse

Read more

Hypertherm plasma cutting systems are increasing productivity and profitability in shipyards and marine construction plants around the world. From the largest cargo vessels to submarines to recreational craft, our products play a key role in all phases of fabrication and repair, providing safer, dross-free cuts for more efficient welding and tighter fit-up.

While modern shipbuilding methods are well-established, shipbuilders can address common operational challenges by adopting newer, safer, and more efficient technology to improve many areas of their value stream.

Single-digit profit margins, shorter delivery timeframes, and general industry pressures, means shipbuilders need to do more in less time, while still keeping yards safe, avoiding costly hazards and inefficiencies.

By choosing plasma, you can mitigate expenses incurred by labor costs, waste, time, and safety risks.

Safety

Minimize risks such as tripping hazards, secondary grinding, and combustible gases to keep your crew healthy and productive, while increasing profitability.

Material handling

Eliminate bottlenecks and reduce the cost of material handling processes in both lost time and safety risks.

Workpiece distortion

Avoid heat-induced warping or buckling, as well as making necessary corrections faster, safer, and easier to maximize operational value.

Secondary operations

Minimize the need for secondary grinding and finishing operations after cutting to reduce risk and make the most of your time and your workforce.

Skilled labor

Get ahead of the skilled labor shortage by shrinking the learning curve for newer employees.

Application [3]

Skeleton removal

-

-

-

Beveling

-

-

-

Temporary attachments

-

-

-

General cutting

-

-

-

Gouging

-

-

-

[1] Include all employees in office, engineering, production, etc. and contractors in the shipyard

[2] Average wages of welders, operators, assemblers, etc., production employees

[3] Calculations are based on 12 mm (1/2") mild steel thickness and standard industry data

* These savings are projected based upon prior observations. Actual results will vary.

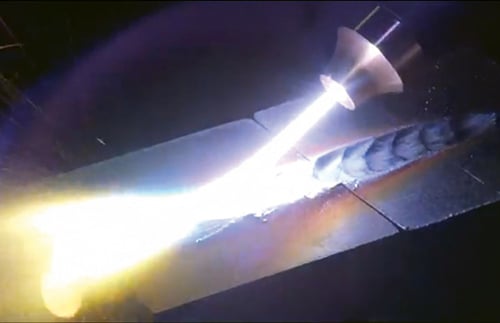

Gouging is often used in shipbuilding operations to remove material, clean surfaces, and prepare weld joints. Gouging with plasma vs. carbon-arc is faster, easier, less noisy, and results in less fumes, smoke, and sparks.

Extended-length torches for hand-held skeleton cutting and removal offer improvements to operator safety and ergonomics, as well as easier material handling and increased uptime.

By using plasma for removal of temporary welded attachments such as lifting lugs and stud weldments, shipbuilding operators can cut quickly and cleanly, flush to the base material with no preheat time and less additional surface grinding required.

After cutting on CNC tables, using plasma to bevel edges for weld preparation provides significant safety and productivity advantages over oxyfuel, including reduction of fumes and fire hazards, and decreased need for secondary grinding, which can lead to ergonomic discomfort and hand-arm vibration injuries.

For general hand-held cutting during fabrication, fit-up, and assembly, replacing oxyfuel torches with plasma systems offers quantifiable advantages in cut quality, speed of cut and set-up, as well as improving the safety of the yard.

Learn about the most common challenges facing the shipbuilding industry today, including information on processes, technology, and the market, so that your operation is safer, faster, and more profitable.