About Plate Saver technology

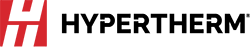

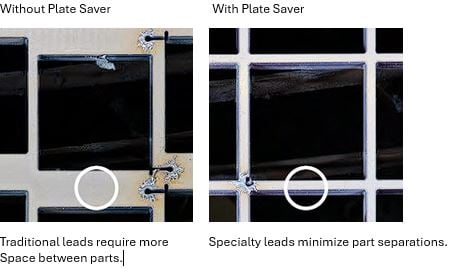

Plate Saver™ introduces new specialty leads to the CAM software when programming jobs for machines equipped with XPR®. It adjusts lead size, style, and location and uses a moving pierce to minimize part separations while at the same time maintaining part quality. The enhanced arc stability feature of XPR X-Definition® plasma quickly stabilizes the plasma torch arc, allowing for shorter lead lengths and closer part placement.

Key business benefits

-

Reduces cost-per-part

Increases material utilization by as much as 14% and reduces cost-per-part

-

Eases carbon footprint

Lowers greenhouse gas emissions by producing the same parts with less steel

-

Minimizes part separation

Utilizes a moving pierce to minimize part separations while maintaining part quality

Plate Saver minimizes part separations

Splash zone helps maintain cut quality

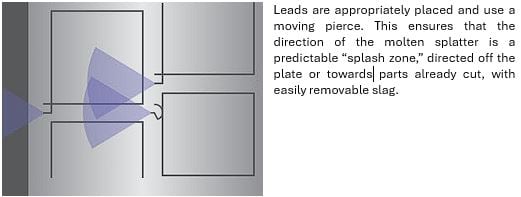

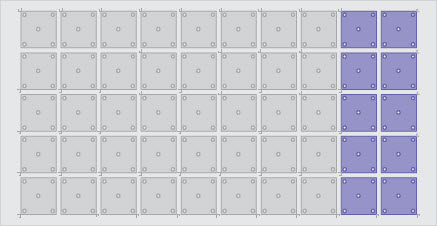

Nesting with square parts

Plate Saver is most effective when nesting square or rectangular parts. The below example shows square parts yielding a dramatic 14 percentage point improvement in true utilization rate:

Without Plate Saver

40 parts, 56% utilization

With Plate Saver

50 parts, 70% utilization

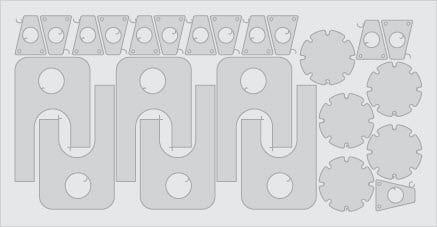

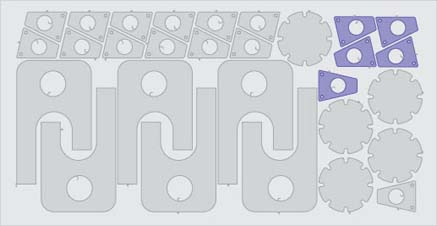

Nesting with mixed parts

Plate Saver yields an impressive three percentage point improvement on average for jobs containing a mix of differently shaped parts. This results in significantly lower annual material costs and cost-per-part—resulting in higher profitability.

Without Plate Saver

24 parts, 62% true utilization

With Plate Saver

29 parts, 65% true utilization

Plate Saver cost savings calculator

Enter basic information about your current plate usage to calculate your potential material cost savings and scrap reduction with Plate Saver.

Calculate My Savings

System requirements

-

For use with mild steel, X-Y cutting only

-

Applies to material thickness and appropriate plasma process combinations between 13 mm (0.5 in) and 32 mm (1.25 in)

-

Hypertherm XPR® X-Definition® plasma system

-

ProNest® or CAM software from an authorized partner

-

EDGE® Connect or CNC from an authorized partner

Note: Plate Saver moving pierce technique may increase sparking and spray.

Where to buy a Plate Saver capable machine

To find an authorized Hypertherm partner in your area, please use the contact form below and specify your interest in Plate Saver.

Contact an expert

Related content

XPR family cutting solutions

The XPR® plasma family represents the most significant advancement in mechanized plasma cutting technology, ever.