Results for "electrode"

Products (23)

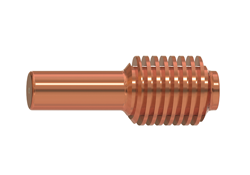

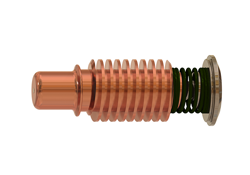

HyAccess electrode: #420137

HyperthermPatented HyAccess™ consumables extend approximately 76 mm (3") beyond standard Powermax consumables to provide the extra reach needed when cutting or gouging in hard to reach or confined spaces.

Pages (4)

Extending parts and consumables life

One of the most common and frustrating problems in plasma-arc cutting (PAC) is short service life of parts. Here are some technical tips to ... Read more

Safeguard your cutting operations with genuine Hypertherm plasma consumables

The only real bargain is real value. Using genuine Hypertherm consumables for your Hypertherm plasma cutting system is the only way to ... Read more

Troubleshooting cut quality problems – cut angularity

How does a plasma cutting system torch operator begin to troubleshoot a cut quality problem? Here we discuss the critical process variables ... Read more