About Rapid Part technology

More than half of production time is often spent moving between cuts—time that could be used to cut faster and increase productivity. Rapid Part uses hardware and software features to reduce cycle time, providing more efficient motion and enabling up to a 100% increase in parts per hour.

Key business benefits

-

Provides more efficient motion

CAM software and select hardware components combine to deliver more efficient motion during the cutting process

-

Halves production time

Rapid Part provides more efficient motion and skips unnecessary steps, reducing production time by up to 50%

-

Reduces cycle time

Rapid Part reduces cycle time and produces up to 100% more parts per hour

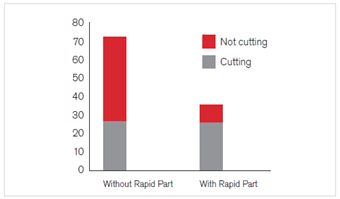

Reduce total production time by half

In this example, non-cutting time (red) is reduced by 80%, lowering the overall production time by 50%.

Note: Testing based on 20.3 cm [8”] flange parts with eight holes each, mild steel, 3.97 mm [5/32”] thickness.

Three ways Rapid Part reduces cycle time

Rapid Part optimizes three critical aspects of the cutting process and executes them automatically through the CNC.

-

Improves cut path

CAM software optimizes the cut path, minimizing the distance traveled from one cut to the next. It also avoids potential collisions, such as part tip-ups that would otherwise require a time-consuming full head raise (Z-axis) motion to traverse safely. -

Features rapid Z-axis/vertical motion

In cases where the torch head must be raised fully, the torch height control features rapid Z-axis/vertical motion capability, including automatic fast-to-slow speed crossover calibration. -

Gas pre-flow

At the beginning of the initial height sensing or machine motion, Hypertherm HPRXD or XPR plasma system gas consoles feature gas pre-flow functionality, saving valuable time on each pierce.

System requirements

- Hypertherm XPR® X-Definition® or HyPerformance® HPRXD® plasma system

- ProNest® with the Collision Avoidance module or CAM software from an authorized partner

- EDGE® Connect or CNC from an authorized partner

- Sensor THC or torch height control from an authorized partner

Where to buy a Rapid Part capable machine

To find an authorized Hypertherm partner in your area, please use the contact form below and specify your interest in Rapid Part.

Related content

XPR family cutting solutions

The XPR® plasma family represents the most significant advancement in mechanized plasma cutting technology, ever.