Maximize Hypertherm plasma performance

SureCut delivers embedded expertise for XPR and HPR plasma systems

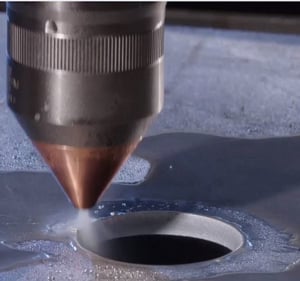

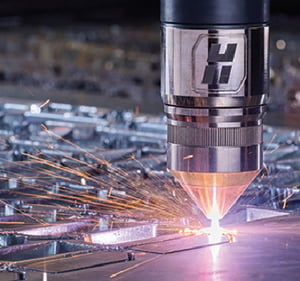

No matter your industry or application, your production floor must cut faster and more efficiently to remain competitive. Hypertherm Associates has collaborated with its global partners for over fifty years to provide our customers with the most significant advances in mechanized plasma cutting technology and automation software to boost production and improve the bottom line.

Our exclusive SureCut technology uses software to automatically embed advanced cutting capabilities into your plasma cutting process, delivering improved outcomes, simplifying cutting operations, and reducing operator intervention.

Utilizing SureCut technology

Most machines equipped with a Hypertherm HyPerformance® HPRXD® or XPR® X-Definition® plasma system come with automatic access to one or more SureCut technologies. The machine operator or CAM software programmer can access these technologies through the user interface, for example, ProNest®, EDGE® Connect, or other CAM or CNC software from an authorized partner. Each technology typically runs automatically, without the need for operator intervention.

For more information, including the supported technologies for your specific machine, please contact your manufacturer.