어떤 플러시 절단 작업이라도 FlushCut™과 함께라면 해결할 수 있습니다!

-

플라즈마 플러시 절단이 산소 연료 절단이나 탄소 아크 절단보다 더 효율적인 이유는 무엇인가요?

-

작업자에게 가장 안전한 플러시 절단 환경을 보장하려면 어떻게 해야 하나요?

-

플라즈마 플러시 절단 자동화를 시작하려면 어떻게 해야 하나요?

55년 이상의 역사를 자랑하는 Hypertherm Associates는 전 세계 절단 전문가들을 지원하기 위해 수세기에 걸친 응용 기술 전문성을 결합해 왔습니다. 고도의 까다로운 도전 과제들도 당사와 함께하면 자신 있게 해결할 수 있습니다. 함께 협업할 수 있기를 기대하며, 귀하의 연락을 기다리겠습니다.

전문가에게 문의하기개요

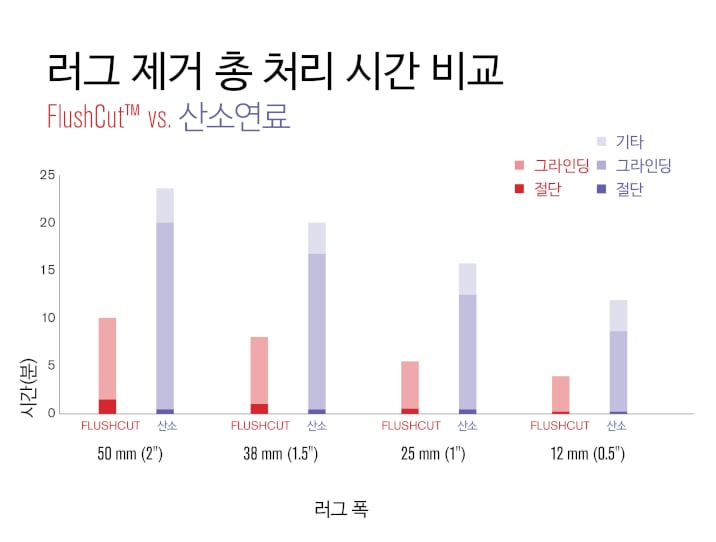

Hypertherm® FlushCut 공정을 선택하면 산소 연료 절단이나 탄소 아크 가우징과 같은 기존 방식에 비해 더 빠르고, 깔끔하며 정밀한 절단이 가능합니다. 비철금속 절단이 잘 되지 않고, 제거하기 힘든 슬래그를 남기는 산소 연료 절단과 달리 플라즈마 절단은 다양한 소재에서 매끄럽고 일관된 절단을 제공하며 열영향부(HAZ)가 최대 10배 더 적습니다. 탄소 아크 방식과 비교했을 때도, 플라즈마 플러시 절단은 슬래그와 파편이 거의 발생하지 않아 그라인딩 작업이 줄어듭니다. 모재에 더 가깝게 절단하고, 플라즈마로 잔여 금속을 세척할 수 있는 FlushCut 기능은 시간 소모적이고 노동 집약적인 그라인딩 작업의 필요성을 줄여 제조업체가 생산성을 높이고 비용을 절감하는 데 도움이 됩니다.

플러시 절단 용도는 다음과 같습니다.

-

자재 운반을 위해 사용된 리프팅 러그, 패드 아이 및 임시 용접 지지대 제거 - 운송 후 취급 보조 장치를 더 깔끔하게 분리할 수 있어 최종 마감 또는 검사를 위한 표면 준비 작업이 줄어듭니다.

-

엔드 캡 제거 - 배관 및 구조물 내부의 구성 요소나 공간에 접근할 수 있어, 유지 관리 또는 개조 작업 시 유용합니다.

-

I형 및 H형 빔에 용접 접근 구멍("랫 홀") 절단- 전체 관통 용접을 해야 하는 용접자가 빔 플랜지에 접근할 수 있어, 구조적 무결성을 향상시키고 엔지니어링 표준 준수를 보장합니다.

-

볼트 및 리벳 제거 - 구조적 또는 기계적 시스템에서 패스너를 효율적으로 분해하거나 교체할 수 있어 주변 자재의 손상을 최소화합니다.

-

주조 스프루 제거 - 주조 공정에서 발생한 잔여 재료를 제거하여 주조 부품을 깔끔하게 정리하고 치수 정확도와 외관 품질을 보장합니다.

-

포스트텐션 케이블 테일 절단 - 콘크리트 구조물에서 인장 작업 후 노출된 케이블 끝단을 정밀하게 절단하여 안전성 향상과 외관 개선, 설계 사양 준수에 기여합니다.

플라즈마 플러시 절단의 주요 이점

플라즈마 플러시 절단은 절단 속도, 범용성, 모서리 품질 측면에서 탁월하여 제조 및 가공에 이상적입니다.

-

더 빠른 절단 속도

특히 얇은 소재와 비철금속에서 산소 연료 절단이나 탄소 아크 절단보다 훨씬 더 빠르게 절단합니다.

-

다양한 소재 호환성

철금속에만 한정되는 산소 연료 절단과는 달리 스테인리스 스틸 및 알루미늄 등 다양한 금속에 효과적입니다.

-

더 깔끔한 모서리 품질

최소한의 슬래그나 드로스를 생성하여 매끄럽고 균일한 모서리를 만들어 그라인딩 또는 2차 마감 작업을 줄입니다.

-

열영향부(HAZ) 최소화

열 변형을 최소화하고 용접 준비 및 구조 응용 분야에 중요한 소재 무결성을 유지합니다.

-

안전성 향상

화염 노출과 탄소 아크 스파크를 제거하여 화재 위험을 줄이고 작업자의 안전을 향상합니다.

-

자동화에 최적화

로봇 시스템 및 CNC 플랫폼과 쉽게 통합되어, 대량 생산 환경에서도 일관되고 반복 가능한 플러시 절단을 구현합니다.

플라즈마 플러시 절단: 효율적이고 정밀한 기술

플라즈마 플러시 절단은 제조 자동화 환경과 다양한 금속을 다루는 작업에 이상적인 가장 효율적이고 정밀한 절단 방식입니다

| 특징 | 플라즈마 절단 | 산소 연료 절단 | 탄소 아크 절단 |

|

절단 속도 |

얇은 금속과 중간 두께의 금속을 빠르게 절단하여 생산성과 효율성 향상 | 특히 얇은 금속에서 더 느린 절단 속도 | 중간 속도, 얇은 금속에서 산소 연료 절단보다 빠르지만 정밀도는 낮음 |

|

범용성

|

알루미늄, 스테인리스 스틸 및 구리를 포함한 모든 전도성 금속 절단 | 강철 및 철과 같은 철금속에 한정됨 | 대부분의 금속, 특히 탄소강에 적합, 비철금속에는 효과가 덜함 |

|

모서리 품질

|

드로스가 거의 없고 매끄럽고 정밀한 모서리를 생성하여 그라인딩 또는 기타 후가공을 최소화 | 거친 가장자리와 슬래그를 남기며, 종종 광범위한 그라인딩 또는 정리가 필요 | 거친 작업에는 적합하지만, 정밀 절단에는 이상적이지 않음 |

Powermax SYNC의 플러시 절단

Powermax SYNC 플라즈마 절단 시스템은 첨단 인텔리전스 기술과 혁신적인 일체형 카트리지 소모품을 결합하여 설정을 간소화하고, 운용 비용을 절감하며, 절단 및 가우징 성능을 향상시킵니다. 색상으로 구분된 카트리지는 부품 혼동을 방지하고 재고 관리를 간편하게 해주며, SmartSYNC ® 토치는 자동으로 최적의 작동을 조정해줍니다. 교체 가능한 토치 스타일과 용도별 카트리지를 통해 다양한 작업 환경에 유연하게 대응할 수 있습니다. 소모품 수명 종료 감지 기능과 기존 소모품보다 최대 두 배 더 오래가는 카트리지 수명 덕분에 효율성과 생산성이 극대화됩니다.

일반적인 응용 분야에는 플러시 절단, 장거리 절단, 드래그 절단, 베벨 절단, 가우징 및 Fine Feature 절단 등이 있습니다.

특허받은 FlushCut 소모품

특허를 받은 Powermax 시스템용 FlushCut™ 소모품 및 카트리지는 플라즈마 아크가 토치에서 45도 각도로 발사될 수 있도록 해주는 비중심 노즐 보어로 설계되어 있어, 러그와 부착물을 평평한 바닥면으로 제거할 수 있으며, 이를 통해 러그나 부착물의 재사용 가능성을 높입니다. 각진 노즐 보어 설계와 평평한 가이드 쉴드는 베이스나 공작물에 5mm(3/16인치) 미만의 잔류물을 남기는 플러시 절단을 가능하게 하여 그라인딩 및 후속 공정을 줄여줍니다.

SmartSYNC 토치

Hypertherm의 Powermax45/65/85/105 SYNC® 플라즈마 시스템 및 어댑터가 장착된 Powermax45® XP용 SmartSYNC® 토치에는 소모품을 간단하게 돌리기만 하면 되는 트위스트 장착 방식과 수동식 모델의 편리한 전원 및 암페어수 조정 제어 기능이 있어 작업자가 전원공급장치에 가지 않더라도 소모품 교체 및 작업 전환이 가능합니다. 이는 소모품 교체 시간을 약 10초로 단축하고, 카트리지에 맞춰 시스템이 자동으로 설정되어 가동 중단 시간, 문제 해결, 낭비, 교육 시간을 최소화합니다.