Plasma cutting vs. fiber laser cutting

When comparing plasma cutting against laser, plasma excels across a wide range of material thicknesses. It’s especially advantageous when cutting metal greater than 16 mm (5/8”) in thickness as it’s faster, has a lower initial investment and direct operating cost, and is more forgiving when working with imperfect or reflective metal. In addition, high-definition plasma cuts bolt-ready holes and bevels easily.

Benefits of choosing plasma cutting over laser cutting

Choosing which technology depends on the specific job and the cutting outcomes that best fit your requirements. Because it’s a newer technology, fiber laser is sometimes assumed to be superior and more modern. However, while fiber laser has only recently been used to cut metals thicker than sheet gauge, plasma has been perfected over the last several decades to produce high-quality cutting outcomes with low initial investment and operating costs.

-

Plasma produces excellent cut quality

-

Plasma cuts bolt-ready holes and weld-ready bevels

-

Laser tolerances come with cost tradeoffs

-

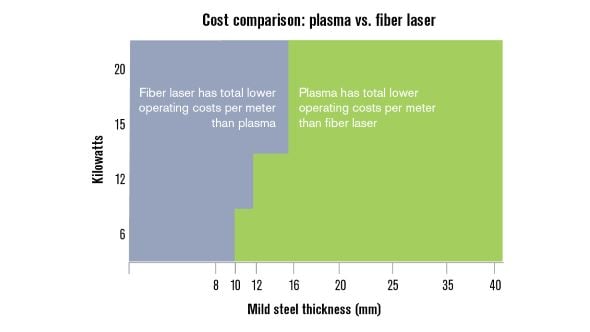

Plasma is fast

-

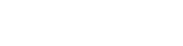

Plasma costs less

-

Plasma is versatile

-

Plasma is robust and reliable

Fill out the form and our experts will contact you for more information.